|

October, 2008

Nanotechnology In Gas Detection Has Appeal

By Michael D. Shaw

What Is Nanotechnology?

Nanotechnology is the manipulation and manufacture of materials and devices on the scale of atoms or small groups of atoms. The scale here is typically measured in nanometers, or billionths of a meter. It is noted that materials built at this scale often exhibit distinctive physical and chemical properties due to quantum mechanical effects.

Indeed, as is pointed out on the website of the College of Nanoscale Science and Engineering of the University of Albany…

The behavior of materials at the nanoscale is often very different from when they are in a larger form. Nanomaterials can be stronger, lighter, more easily recyclable, and are often able to conduct heat or electricity in a different way. They can even change color.

These special attributes are already being used in a number of ways, such as in semiconductors, scratch-free paint, wrinkle and stain-resistant fabrics, sunscreen lotions, skis, and photographic paper.

We can add the further practical—and beneficial—application of embedding silver nanocrystals in bandages, to kill bacteria and prevent infections.

Of course, nanotechnology has existed in nature since the dawn of life, with enzymes to catalyze the synthesis of huge molecules, DNA for information storage, and molecular motors powered by adenosine triphosphate.

Why Do Nanomaterials Behave Differently From Macro Scale Materials?

Besides the quantum mechanical effects, one must also consider the very large surface-to-volume ratio of these structures. As such, no atom is far from a surface or interface, and this higher-energy location influences material properties.

For example, it has long been known that the reactivity of a metal catalyst particle generally increases appreciably as its size is reduced. Macroscopic gold is chemically inert, but at nanoscale, gold becomes extremely reactive and catalytic, and even melts at a lower temperature.

Nanoscale Gas Detection

Nanotechnology, in theory, has quite an appeal in the world of gas detection. After all, nearly every gas detector is indicating some property that occurs at the molecular level, and operating within that world seems only logical. Let’s take a look at a few current technologies.

Metal oxide nanowires

Metal oxide gas sensors were first introduced by Taguchi in 1962, and have undergone modifications and improvements ever since. In keeping with the notion of catalytic properties improving with decreased size, nanosize powders have been used to produce metal oxide gas sensors, and sensitivity does improve dramatically.

A relatively new wrinkle is to utilize electrical field enhanced oxidation techniques to fabricate In2O3, SnO2, ZnO, and WO3 nanowires that could potentially be used for sensing NO2, O3, and CO. A typical nanowire is about 50 nanometers wide, and researchers are trying to make them even smaller.

While metal oxide gas sensing has problems with specificity, one idea is to create arrays of nanowires, each tuned slightly differently. This would not only create a sort of “electronic nose,” but processing the multitude of information could deliver both a qualitative and quantitative analysis of the environment.

As they say, though, much work remains to be done.

Carbon Nanotubes

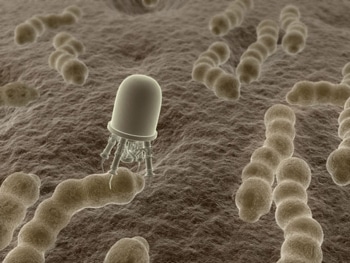

A carbon nanotube is a long cylindrical arrangement of carbon atoms, that can be thought of as a sheet of graphite rolled into a cylinder. Perhaps the most studied tubes are the single-walled carbon nanotubes (SWNT). An SWNT can be likened to a nano-sized piece of chicken wire, whereby each “cell” is formed of a hexagonal ring of carbon atoms.

Gas detection is accomplished by using an array of SMNTs aligned across microelectrodes. The carbon nanotubes act as molecular wires.

When a particular gas molecule binds to the carbon nanotube, the tube’s electrical conductivity changes. Because each gas affects conductivity differently, gases can be identified by measuring the conductivity change after binding.

Excellent sensitivities have been claimed for these devices—down to parts-per-trillion levels. A good deal of effort within this technology is being directed toward sensing compounds of interest to national security, such as nerve agents.

Performance can be enhanced—or as the researchers call it—”functionalized” with various doping materials being applied to the nanotube. Here again, specificity is an issue, and many labs are working on improving this technology.

Microcantilevers

Technically, these are not nanoscale devices. Rather they are considered a so-called MEMS device. MEMS stands for Micro-Electro-Mechanical Systems, and is the integration of mechanical elements, sensors, actuators, and electronics on a common silicon substrate through microfabrication technology.

The terms MEMS and nanotechnology have been linked for some time, and many authorities in these fields cross disciplines. Thus, we include microcantilevers in this article.

Unlike many other types of gas sensors, microcantilevers are simple mechanical devices. They are tiny plates or leaf springs, typically 0.2-1 micrometers thick, 20-100 micrometers wide, and 100-500 micrometers long—connected on one end to an appropriate support for convenient handling.

Think of a microcantilever as a miniaturized diving board that moves up and down at a regular interval. This movement changes when a certain mass of the compound to be analyzed is specifically adsorbed on its surface, similar to the change when a person steps onto the diving board.

Thus, molecules adsorbed on a microcantilever cause vibrational frequency changes and deflection of the microcantilever. Various methods are used to measure the deflection of the cantilevers, including piezoresistive, optical, capacitive, and interferometry.

As with the carbon nanotubes, coatings can be applied to the microcantilevers to increase sensitivity and promote better specificity.

Nanocantilevers

In April of 2005, a group of researchers using nanocantilevers 90 nanometers thick, and made of Si3N4, announced that they were able to detect a single piece of DNA—1578 base pairs in length. The group, led by Harold Craighead, Ph.D., of Cornell University, stated that they can accurately determine when a molecule with mass of about 0.23 attograms (1 attogram = 10-18 gram) lands on an individual nanocantilever.

Scanning laser beams were used to measure the vibrational frequency of the cantilevers. So far, though there is no news regarding applying this technology to gas detection, and one can only imagine the practical difficulties that could ensue if one actually tries to detect a few molecules!

The Takeaway

While nanotechnology has fantastic potential, we would advise not getting rid of your traditional gas detector anytime soon.