- Gas detection and data logging ensure systems’ safety and efficiency.

- Data logging and other technology can be a powerful asset to any manager.

- Data logging can support analysis, decision support systems, early warning, remote monitoring, maintenance strategies, performance optimization, and regulatory compliance.

Data logging in gas detection integrated with detectors is used across industries to monitor and measure gas concentration data and analyze and identify trends. Organizations can proactively mitigate risks by leveraging data-driven insights and safeguarding personnel, assets, and the environment. In this article, you will get more details on possible applications and benefits of using real-time data from logging.

What does a Data Logger Do?

Data loggers are electronic tools that automatically monitor and measure selected parameters, which are analyzed externally over time. The data logger collects information continuously from one or several sensors with varied functions and sends the information to a computer for storage, updating, and analysis.

Data logging can be manual; however, automatic electronic devices are more accurate and efficient, and measurements can be taken periodically. Moreover, these devices save time and costs and can operate in toxic and harmful atmospheres for personnel.

Earlier gas detection programs consisted only of sensors and effective maintenance through calibration and bump testing. Now, data logging is an essential function of the tools and the job.

Besides sensors for gas detection, data logging has some other essential requirements:

- Software that consolidates information from various sensors in one location and presents it in an easy-to-understand format.

- A good internet connection is necessary to simplify setup and receive remote alerts via a mobile device or computer.

Safety managers operating gas detectors with data logging capacity must have protocols to address data safety and integrity concerns to protect staff welfare:

- Data safety: Portable gas detectors collect sensitive worker location data and other information that must be stored safely to protect staff.

- Data integrity: Portable and fixed gas detectors collect data about the working environment, which is essential to ensure staff health and safety. So, the information stored and updated must be accurate, complete, and reliable even in the long term.

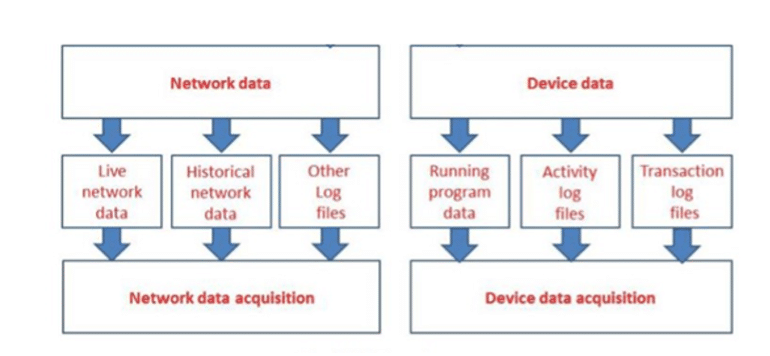

Figure 1: Representation of an ICS, Van Vliet et al. 2015. ( Image credits: https://arxiv.org/ftp/arxiv/papers/1611/1611.01754.pdf)

Key Features and Applications of Data Logging

Gas detectors with data logging in industrial settings designed for monitoring emission levels have some standard features and applications in enhancing process safety across various industries, as discussed below.

Core Features of Data Logging Systems

- Storing and Accessing Data: Online real-time data recording offers the advantage of easy accessibility from anywhere, enabling users to take adequate measures promptly. The use of SD cards helps prevent data loss.

- Measurement and Presentation: Graphical representation enhances insights people can get from data. Syncing data with Excel sheets facilitates compatibility with data analytics software, thereby enhancing industry efficiency.

- Data Analysis for Better Detection: Utilizing data loggers to provide more detailed information in real-time and improve analysis is crucial to maintaining air quality measurement.

- Realtime Monitoring and Alarming: Data logging systems often incorporate real-time monitoring capabilities with automated alarming functionalities. This enables operators to promptly respond to deviations from normal operating conditions, mitigating potential safety risks before they escalate.

- Remote Monitoring: IoT integration enables seamless data transfer to the internet, facilitating remote monitoring of parameters like gas concentration. This approach enhances reliability and reduces the need for physical presence at monitoring sites, improving staff safety.

Critical Applications of Data Logging

Enhancing Safety and Efficiency

- Early warning systems: Data loggers are crucial components of early warning systems. Data logging enables the monitoring of critical parameters and deviations from expected values. It allows for the early detection of irregularities or abnormal trends, signaling potential hazards before they escalate into safety incidents.

- Data-driven decision support systems: The data logged provides operators with valuable insights and data for decision-making processes and proactive measures. Data can also be used in decision support systems that apply algorithms and analytical techniques to historical and real-time data to identify patterns, predict potential problems, and suggest optimal courses of action. This proactive approach can help operators maintain safe operating conditions, prevent downtime, and enhance efficiency.

Operational Optimization

- Performance Optimization: Continuous data logging facilitates the optimization of processes and equipment by identifying inefficiencies or areas for improvement. Organizations can fine-tune operational parameters by analyzing historical data trends to enhance safety margins and overall performance.

- Maintenance: Maintenance strategies have evolved from breakdown to time-based preventive and condition-based maintenance. Organizations can implement predictive maintenance strategies by analyzing equipment performance data. By identifying early signs of equipment degradation or impending failures, proactive maintenance can be scheduled, minimizing the risk of unexpected downtime and safety hazards. The data can also be used for condition-based maintenance (CBM), emphasizing the importance of data acquisition in CBM programs for machinery fault diagnostics and prognostics.

Technical and Regulatory Integration

- Performance Testing of Machinery: Electronic data handling systems play a crucial role in modern analytical systems, reducing errors and facilitating data management. Regular testing of data systems using known data ensures accuracy and reliability in performance evaluation.

- Training and Decision Support: Historical data logs serve as valuable training resources for personnel, enabling them to understand past incidents, learn from them, and make informed decisions in real-time scenarios.

- Integration with ICS: Industrial Control Systems (ICS) are vital in critical infrastructures, ranging from manufacturing plants to power stations. Integrating gas detection and data logging is often part of a comprehensive safety and monitoring strategy in ICS setups like Distributed Control Systems (DCS) connected to Supervisory Control And Data Acquisition (SCADA) systems. These systems enable real-time monitoring of industrial processes, rapid response to alarms or abnormal conditions, and detailed post-incident analysis through access to historical data.

- Industrial forensics involves investigating incidents or anomalies within industrial systems to determine their causes and prevent future occurrences. Gas detection data and logged parameters can provide invaluable insights into what happened leading up to an incident, helping forensic analysts piece together the sequence of events and identify contributing factors. It aids in conducting thorough root cause analyses and implementing corrective measures to prevent recurrence.

- Regulatory Compliance: Many industries are subject to stringent regulatory requirements about safety and environmental standards. Data logging helps organizations demonstrate compliance by maintaining comprehensive records of operational parameters, audits, and safety inspections. Compliance in data logging ensures that the data collected meets the requirements set forth by relevant regulations or standards. This may include aspects such as the frequency of data collection, the accuracy of measurements, the storage and retention of data, and the ability to produce records for regulatory inspections or audits.

Detection and Logging by AccuSafe

Interscan’s AccuSafe is a continuous gas detector with up to ten sensor modules that report to a single controller through the network Modbus TCP/IP. TCP refers to the Transmission Control Protocol and IP to Internet Protocol, which allows devices to exchange information and route it. Data acquisition is built into the AccuSafe along with remote annunciators or visual and audio alarms.

Safety managers can remotely control AccuSafe devices and their alarms and download data using the integrated software. Sensors are available for around twenty toxic gases.

Written by:

Vijayalaxmi Kinhal

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

This article has been AI-assisted and was edited for accuracy.

Sources

Jardine, A. K., Lin, D., & Banjevic, D. (2006). A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mechanical systems and signal processing, 20(7), 1483-1510.

Hernández-Rodríguez, E., González-Rivero, R. A., Schalm, O., et al. (2023). Reliability Testing of a Low-Cost, Multi-Purpose Arduino-Based Data Logger Deployed in Several Applications Such as Outdoor Air Quality, Human Activity, Motion, and Exhaust Gas Monitoring. Sensors, 23(17), 7412.

Islam, M. S. (2018, February). An intelligent system on environment quality remote monitoring and cloud data logging using Internet of Things (IoT). In 2018 International Conference on Computer, Communication, Chemical, Material and Electronic Engineering (IC4ME2) (pp. 1-4). IEEE.

Lee, H., & Awbi, H. B. (1998). Effect of data logging frequency on tracer gas measurement.

MacDougall, D., & Crummett, W. B. (1980). Guidelines for data acquisition and data quality evaluation in environmental chemistry. Analytical chemistry, 52(14), 2242-2249.

Munsadwala, Y., Joshi, P., Patel, P., & Rana, K. (2019, April). Identification and visualization of hazardous gases using IoT. In 2019 4th International Conference on Internet of Things: Smart Innovation and Usages (IoT-SIU) (pp. 1-6). IEEE.

Van Vliet, P., Kechadi, M. T., & Le-Khac, N. A. (2016). Forensics in industrial control system: a case study. In Security of Industrial Control Systems and Cyber Physical Systems: First Workshop, CyberICS 2015 and First Workshop, WOS-CPS 2015 Vienna, Austria, September 21–22, 2015 Revised Selected Papers 1 (pp. 147-156). Springer International Publishing.