- Understanding and ensuring the calibration of gas analysis instruments are crucial for maintaining optimal working conditions and minimizing hazards.

- A calibrated instrument is fundamental for precise readings, compliance with standards, avoidance of false alarms, and adaptation to environmental shifts. It also strengthens trust in safety systems.

- Access to high-quality calibration is vital, and while traditional methods can be time-consuming, Modern Sensor Systems offer innovative solutions to simplify the process.

Gas detectors can stop working accurately for various reasons. A calibrated instrument ensures that the sensors can effectively alert us to potential gas hazards, contributing to overall safety in multiple settings. Calibration also helps industry professionals meet many regulatory obligations. This article focuses on the importance of calibration and introduces a new approach to maintaining it, courtesy of advanced sensor programs.

Non-Calibrated Instruments Cause Accidents

Non-calibrated gas detectors can lead to life-threatening accidents.

For example, a gas detector failed to detect flammable vapors, leading to a fatal explosion during hot work in an incident reported in 2020 in the UK.

Investigations revealed that a critical factor was the adsorption of flammable vapor by substances in the sample tube, causing a false conclusion that the area was free of flammable vapors. Laboratory testing showed significant delays in achieving readings with the unsuitable sample tube at a 50%LEL (lower explosion limit) concentration of the substance. The time needed for a non-zero reading was extended by 1 minute and 15 minutes to get a 90% reading. After calibration, the same sample tube and gas detector detected the methane gas in less than five seconds.

Such incidents highlight the importance of selecting proper gas detection instruments and verifying that they work through bump testing and calibration.

Reasons for Testing Gas Detectors Calibration

Instruments can stop functioning properly for various reasons. Environment, external contaminants like grease, physical knocks, drops, etc.

Safety managers and industry professionals should test gas detectors to ensure workers’ safety and health. Calibration helps industries in other functions and is described below.

- Ensures safety and accuracy: Ensures accurate measurement of hazardous gases, minimizing misreadings. Proper calibration testing maximizes the speed of response and reliability of gas detectors in critical situations. Improper calibration may lead to insensitivity to dangerous gas levels, putting people and operations at risk.

- Detects device wear and tear: Gas detectors face daily abuse, including exposure to extreme conditions and external contaminants. Factors like temperature, humidity, sensor poisoning, and physical impacts can affect sensor accuracy. Testing calibration helps safety managers identify defects to replace faulty instruments and avoid incidents.

- Mitigating false alarms: Prevents unnecessary evacuations, disruptions, and complacency caused by frequent false alarms.

- Provides information for remedial assistance: An accurate gas detector provides correct readings of even trace amounts of gases. The data could be necessary in cases of gas leaks to guide subsequent measures like evacuation or the medical attention that will be necessary.

- Sensor drift and aging: Testing calibration addresses sensor drift and degradation over time, ensuring that the detector’s readings align with the reference. You can also minimize the impact of sensor drift by making necessary adjustments during calibration.

- Environmental adaptability: Adjusts for temperature, humidity, and atmospheric pressure changes to maintain sensor accuracy. Regular calibration tests compensate for environmental variables that can impact detector performance.

- Record keeping and liability: Maintaining thorough calibration records demonstrates a commitment to safety management. Well-documented records can mitigate legal liabilities and enhance an organization’s credibility in case of incidents.

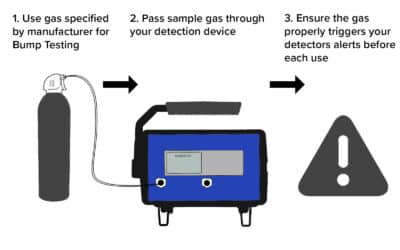

- Confidence in safety systems: Regular bump testing instills confidence in employees and management regarding the optimal condition of safety systems. A properly tested and calibrated gas detector is a testament to an organization’s dedication to safety, providing accurate information and timely alerts during emergencies.

- Regulatory compliance: Regulations vary, but properly calibrated instrumentation is often required, and maintaining logs helps comply with the employer, job site, or country regulations. Reporting calibrated gas detectors is often necessary to meet safety standards and legal requirements.

Proper calibration is essential for maintaining the precision and reliability of gas detection instruments in various environments.

Calibration and Reliability of Gas Detection

In traditional gas detection, calibration involves adjusting the sensor’s response to match a known gas concentration. This is essential for verifying the accuracy of the instrument’s readings, particularly for alarms and display accuracy. However, Interscan’s innovative technology now simplifies this process.

Interscan’s advanced systems significantly reduce the need for frequent manual calibrations. Our instruments are engineered to maintain accuracy over extended periods, only requiring periodic testing to confirm their precision. This ensures that our detectors are reliable, providing peace of mind and safety in critical situations.

While the calibration frequency for traditional detectors can vary based on the device and manufacturer’s advice, Interscan’s advanced solutions and SensorExpress program streamline sensor management, minimizing downtime and maximizing safety. Following these updated guidelines ensures optimal performance of gas concentration readings without the previous calibration burdens.

Transitioning from Manual Calibration to an Advanced Calibration Program

In the evolving landscape of gas detection, transitioning from manual calibration to an advanced calibration program epitomizes the synergy of tradition and innovation.

Traditional Calibration Methods

Historically, calibrating a gas detector involved a meticulous two-step process. Initially, technicians would zero the device in an environment free of hazardous gases to establish a baseline, often using synthetic air or nitrogen. Following this, they would introduce a calibration gas with a known target gas concentration to adjust the sensors, ensuring they accurately detected and measured the specific hazardous gases in the work environment.

Adopting New Sensor Technologies

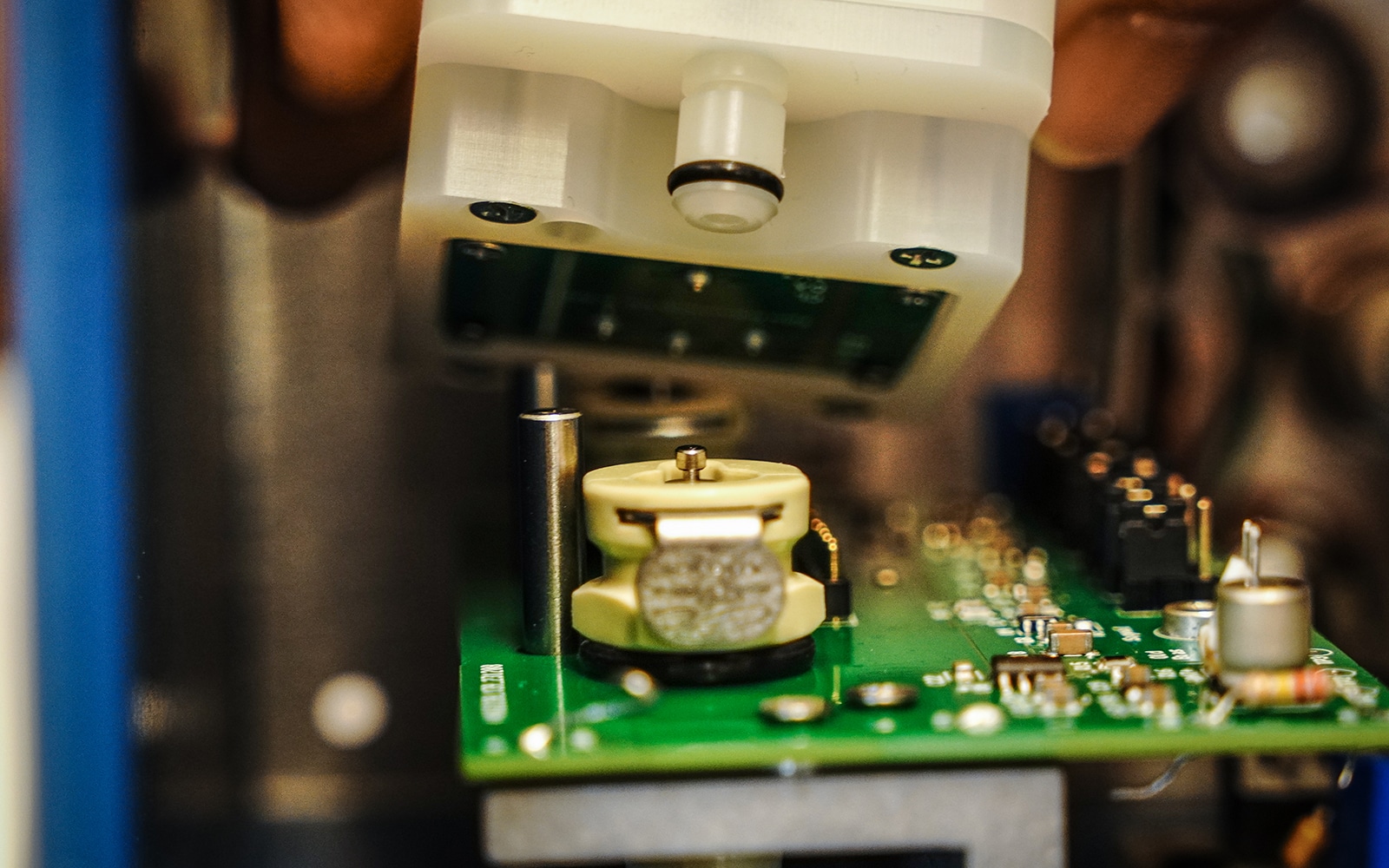

Nowadays, the preferred method for maintaining detector accuracy is to replace the sensor entirely. Interscan’s new program offers an effortless solution with pre-calibrated sensors, ensuring minimal downtime and guaranteed precision. Instead of manually calibrating the devices on-site, users can quickly receive and install a factory-calibrated sensor specifically designed for easy integration into Interscan instruments.

Bump Testing and Annual Calibration

Despite the advancements in sensor technology, regular bump testing remains a crucial practice to verify that the detectors are functional and alert in the presence of gas. This quick check provides immediate validation of operational safety. Additionally, Interscan recommends sending the instrument for a comprehensive calibration every year, ensuring that the device remains at peak performance and adheres to the most rigorous safety standards.

Embracing this advanced calibration program signifies a commitment to safety, precision, and efficiency, heralding a new era in gas detection.

Calibration Gas

Calibration gas is crucial for ensuring the accuracy of gas detectors and analyzers. It allows users to verify instrument readings by exposing them to known concentrations of gases. The traceability of calibration gas to national or international standards establishes a reliable reference point. Key parameters, such as Preparation Tolerance (PT) and Certification Accuracy (CA), contribute to the reliability of calibration gas standards. Safety considerations are essential, as calibration gases may contain toxic and flammable components.

Interscan now provides the GENie EC by Advanced Calibration Designs, a top-tier calibration gas generator. This state-of-the-art instrument offers a vast improvement over traditional methods, producing a variety of gases such as hydrogen sulfide, chlorine, and nitrogen dioxide.

With its interchangeable cells, the GENie EC affords unprecedented flexibility and economy, streamlining the calibration process while ensuring maximum efficiency and minimal waste.

Written by:

Vijayalaxmi Kinhal

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Source

Health and Safety Executive. (n.d.). Failure to detect dangerous gas/vapour due to incorrect specification of sample tube. Retrieved from

https://www.hse.gov.uk/safetybulletins/failure-to-detect-dangerous-gas.htm