Recognizing and eliminating dangers becomes essential to maintaining safety in a world where the unseen poses the most significant threats. These dangers are particularly true for numerous sectors that deal with invisible but potentially deadly gases. Modern gas detection technologies, which continually work in the background to safeguard the safety of both people and the environment, are the unsung heroes in this situation.

This article seeks to help safety managers navigate the confusing world of gas detection technology by providing knowledge about their uses, benefits, and potential drawbacks. Read on to learn more about the different gas detection technologies available.

Understanding the Need for Gas Detection

Various gases represent potential risks, from hydrogen sulfide in wastewater treatment plants to carbon monoxide in underground mines. The crucial function of gas detection systems is to guarantee the safety of these surroundings, supporting the jobs of safety managers. Unfortunately, there have been several sad occurrences in the history of industrial safety when the lack or failure of efficient gas detection systems led to devastating outcomes. The 1984 Bhopal gas catastrophe serves as a somber reminder of this, underscoring the significance of accurate gas detection. In this incident, a leak of the chemical methyl isocyanate resulted in thousands of fatalities.

Overview of Gas Detection Technologies

Gas detection technology has advanced significantly over the years. What were formerly simple techniques, like the fabled “canary in a coal mine” system, are now sophisticated, sensor-based systems that can detect a wide range of harmful gases. As a result, we now have a wide range of technologies available to us, each specialized to specific requirements and applications and precisely tuned to transform the invisible into a controllable, quantifiable object.

Infrared (IR) Gas Detectors

Yazar: Şeymanur Topuk, Karf&Scoot

İzinsiz kopyalanması ve kaynak gösterilmeden alıntılanması yasaktır – https://www.karfandscoot.com/en/infrared-gas-sensors/

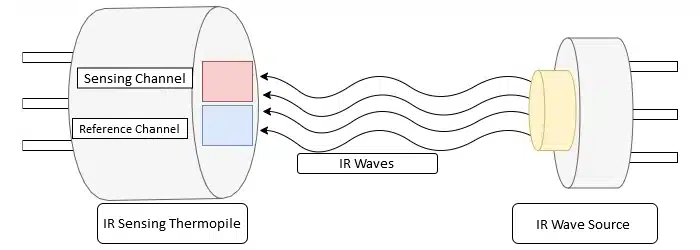

The sentinels of the industry, infrared detectors, use the power of infrared light to detect the presence of dangerous substances. They work by projecting a beam of infrared light into the atmosphere, which the gas molecules absorb. The detector then measures the still present light and uses that measurement to determine the gas concentration. Their primary use is in areas where flammable gas detection is necessary. Nevertheless, IR detectors have their limitations, just like any other device. For example, this method can be challenging to detect specific gases since they need to absorb infrared light better.

Catalytic Sensors

Catalytic sensors detect gas through a combustion process, acting as small laboratories. When gas interacts with one of the two pellistor elements in them, it oxidizes, producing heat and changing the pellistor’s resistance. This variation represents the gas concentration. Due to their dependability and cost-effectiveness, catalytic sensors are widely used to detect flammable gases. They do, however, have a weakness. As a result, they may deteriorate over time and require oxygen to function.

Electrochemical Gas Sensors

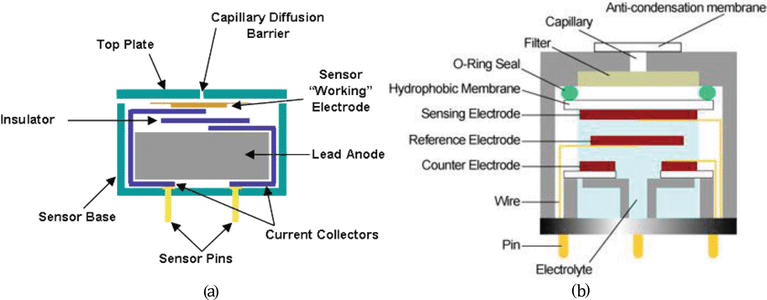

(a) Amperometric cell sensor and (b) potentiostatic cell sensor.

Igor Cretescu, Doina Lutic and Liliana Rosemarie Manea – Intechopen

https://www.intechopen.com/chapters/55305

Like biochemists, electrochemical sensors produce a chemical reaction, producing an electric current proportional to the gas concentration. These sensors are essential in many industries because they can detect harmful substances in low quantities. Even though these sensors have excellent sensitivity and selectivity, variations in humidity or temperature may still have an impact.

Semiconductor Gas Sensors

Metal-oxide-semiconductor sensors (MOS), another name for semiconductor sensors, work by changing the resistance of the semiconductor material in the presence of detectable gases. The reaction between the gas and the semiconductor material causes the sensor’s resistance to vary when exposed to the gas. These sensors are beneficial for spotting chemicals like nitrogen dioxide and carbon monoxide.

Although operating at ambient temperature is beneficial, semiconductor sensors have drawbacks, such as sensitivity to humidity and high temperatures. In addition, they use more power than other sensors and may lose some of their sensitivity with time.

Photoionization Detectors (PID)

PIDs (photoionization detectors) work by ionizing gas molecules using UV light. This process causes the release of electrons and the production of ions, whose current is proportional to the gas concentration. For the detection of volatile organic molecules, PIDs are especially helpful. However, they might be less effective in environments with high humidity or with some inorganic substances.

Maintaining and Calibrating Gas Detectors

Of the type of gas detection equipment employed, regular maintenance and calibration are essential to ensuring their continuous accuracy and dependability. The instrument’s values are tested and adjusted during calibration using a known gas concentration to ensure the detector accurately measures the target gas. On the other hand, routine maintenance makes that the detectors are in good working order and increases their longevity.

Understanding the specifications for maintaining and calibrating gas detectors is an essential part of the job in the context of safety management. Knowing when and how frequently these operations should occur and the warning indicators that a detector might require immediate care are all part of this.

Customers frequently receive thorough instructions on calibrating and maintaining their gas detectors from businesses like Interscan Corporation, providing safety managers with additional help. In addition, the company focuses on customer education and devotion to providing high-quality products.

Choosing the Right Gas Detection Technology

The selection of the best gas detection system is a frequent responsibility of a safety manager. The decision depends on several variables, including the type of gas to be detected, the environment, and industry-specific requirements. Balancing accuracy, dependability, and financial limits is the key to making decisions. With its broad portfolio and creative strategy, Interscan Corporation gradually emerges as a top contender.

The Role of Interscan Corporation in Advancing Gas Detection Technologies

Interscan Corporation has consistently been at the forefront of advancing gas detection technologies. Their commitment to safety and innovation is palpable in their diverse product range that addresses various industrial needs. In addition, the company’s technology continues to evolve, offering more efficient and reliable solutions that outshine many competitors in the market.

Conclusion

The significance of cutting-edge gas detection technologies cannot be emphasized at a time when hidden dangers can have quite evident and frequently disastrous effects. Safety managers are responsible for understanding these technologies and keeping up with their developments. Therefore, if you are thinking about a solution provider, choosing one like Interscan Corporation, which has continuously proven its commitment to innovation and safety, could be crucial to the safety of our teams and our environments.